Session Info

Closed-Cell Insulation Foams Enabled by Coated and Evacuated Nanoporous Materials

Problem

Maintaining temperatures within the building and transportation sectors accounts for more than 40% of global primary energy consumption. Therefore, there is a strong need for sustainable and high-performance thermal insulation technologies that can reduce energy loss, increase indoor space and building longevity, and improve carbon performance of buildings compared to conventional insulation materials such as thermoplastic and thermoset foams as well as vacuum insulation panels (VIPs).

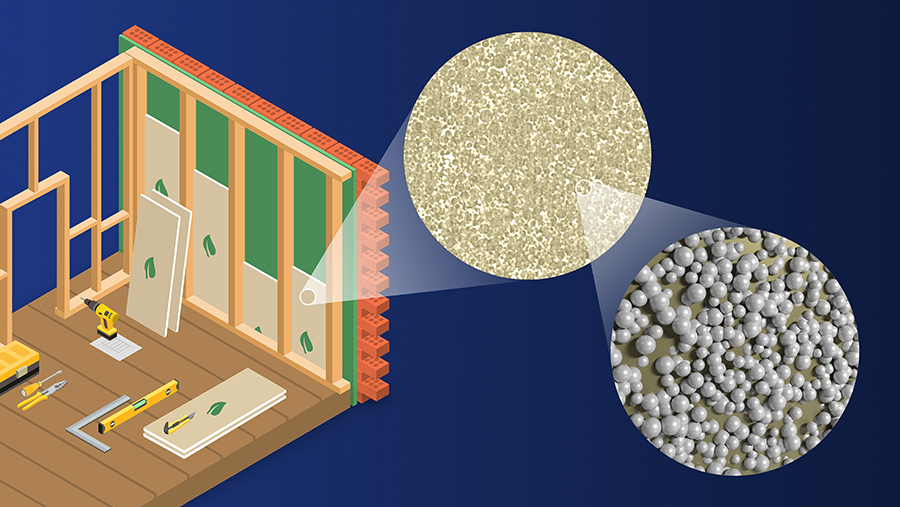

Researchers at Oak Ridge National Laboratory developed an eco-friendly foam insulation for improved building efficiency. Credit: Chad Malone/ORNL, U.S. Dept. of Energy

Solution

The buildings sector needs energy-efficient, slim, low-cost, and robust building envelope solutions to help maintain thermal comfort. Based on industrially relevant processes, ORNL closed-cell thermoset foam insulation technology combines dual hollow filler materials embedded in a thermoset matrix. Currently, this technology platform enables good insulation performance (R/in. ≥ 5), customizable insulation density, and robust mechanical properties and is expected to have better fire and smoke retardancy, all of which are attainable with an easily scalable, more environmentally friendly, and cost-effective fabrication process than commercial thermoset or thermoplastics foam insulation materials.

Impact

As the worldwide demand for energy savings calls for improvements in thermal performance, stricter standards such as the passive house and zero-energy concepts are necessitating development of new insulation materials. With an attractive value proposition of industrially scalable and manufacturable formulations and processes, integration of the ORNL technology into the insulation markets, replacing both the conventional and VIP systems, would provide significant economic and environmental benefit. Providing cost-effective, high-performance, customizable solutions will allow a range of industries to adopt this technology, which will not only decrease end-use energy consumption, but also allow for increased indoor space and reduced thickness of the building components and thus provide a product that is more appealing and valuable to customers.

Publications

Lamm, M. E.; Li, K.; Atchley, J.; Shrestha S. S.; Mahurin, S. M.; Hun, D.; Aytug, T. Tailorable thermoplastic insulation foam composites enabled by porous-shell hollow glass spheres and expandable thermoplastic microspheres. Polymer. 2023, 267, 125652.

Intellectual Property

US Patent Apps. 17/384317 and 17/509869, 2021

“Insulation Foam Enabled by Synergistic Foaming Strategies,” Invention Ref. No. 202305288

“Industrially Processable Thermoset Foam Insulation Dough,” Invention Ref. No. 81944294

Contact

For more information, please contact Eugene Cochran (865-576-2830, cochraner@ornl.gov).